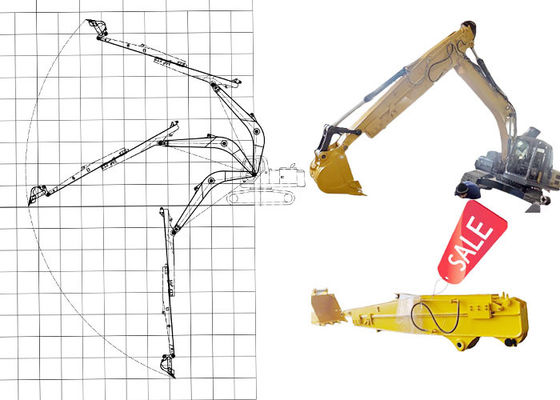

Main Purpose:

This product is primarily used for grabbing and excavating, with the addition of a gripping function based on the excavator bucket. It is commonly used for grabbing stones, wood, iron, and garbage.

Material Selection:

Q355B material is used for processing and production of all components.

Various buckets

Click for more buckets details!

14000㎡ Workshop R&D Team Skillful Workers

We has more than 14000㎡ We use precision drawing There are more than 60 skillful

steel structure workshop with software to achieve the max staffs, 30 welding workers with

lots of high precision working range under the over 5 years welding experience.

processing equipments. premise of safe operation.

Customized Prompt Lead Time 100% Service

1. Fit all brand. 1. Our lead time is 7-15 days. 1. Online support within 24 hours.

2. Color, length, material are customized. 2. Our annual output of excavator 2. Appointment video technical 3. Extra pipeline can be added. boom arms can reach 600 sets. support.

ZHONGHE triple quality control system

The first system is the technical design drawing review mechanism,

The second system is the semi-finished product review mechanism,

(each process has a detection testing for the previous process)

The third system is the finished product testing.

(Before painting, the overall inspection is carried out to check whether the design size matches the welding size, and whether the installation size meets the design requirement.)

To sum up, every single ZHONGHE product has been passed the above three-stage inspection system to ensure that is qualified before shipping.

Large double-sided boring machine CNC plasma cutting machine

Automatic edge milling machine Environmentally friendly spray booth

CE certification & Utility model patent certificates

SUITABLE BRANDS

Bubble bag packaging for most products,

Wooden case for little products, like buckets

Iron frame support for boom arms.

The accessaries and package of excavator long boom arm are subjected to our final confirmation.

1. How do I start to order?

Firstly, talk to our sales about your machine model, working conditions, special needs and deadline. Then we will give you proposals FYR. You will receive a quotation within 24 Hours after confirming the proposal.

2.Why not have boom and stick cylinders in the plan?

A1: First, the whole long arm is lengthening, but the boom just lengthening from its middel sleeve to its end, so the original boom and stick cylinder can be used. Second, using the original parts can save your cost.

3. Are you alaways delivered on time?

We can't promise about the freight but what we can do is shortening our lead time while keep the same quality level. So there will not be any problem even if the sea freight delay for a couple days. Our annual output of various types of excavator boom arms can reach 600 sets.

4. How long is the boom arm can mini excavator be be configured with? Whether it is necessary to increase the counterweight?

A2. Generally speaking, 30-40 excavator longest arm suggests to be 8 meters, can configure 0.1 cbm bucket, no need extra counterweight. 55 excavator longest arm suggests to be 12 meters, can configure 0.1-0.15 cbm bucket, need 0.5 ton extra counterweight. 60-80 excavator longest arm suggests to be 12 meters, can configure 0.15-0.25 cbm bucket, need 0.5-0.7 ton extra counterweight.

It is not recommended to extend boom arm to longest length as min excavator is easy to sloshing.

5. How long will it takes to install a excavator long reach boom?

With reference to the efficiency of Chinese workers, and tools are fully prepared, it only takes one day to complete the disassembly and assembly.

Kindly remind, prepare several containers to fill the oil before disassemble.